Chemical risks in maintenance professions

- Marc Duvollet

- Aug 24, 2025

- 4 min read

Cleaning work requires the handling of chemicals (paint stripper, detergent, descaling agent, degreaser, etc.), most of which are hazardous to health and the environment. Preventive measures are therefore necessary to limit the exposure of employees working in this sector.

The products used in this sector of activity depend on the type of dirt to be removed (grease, scale, burnt residue, various marks and stains) and their choice will be made from suitable detergent products. There are neutral products (e.g.: multi-surface products), acidic products (e.g.: toilet descaler) or basic products (e.g.: oven stripper) which each have their specific use. Detergents have cleaning properties but not disinfectant properties. They are nevertheless essential to combat the proliferation of microorganisms before any disinfection operation. They can be applied by spraying, manually or using a machine or other equipment (broom or brush, etc.). All workplaces are concerned: workshops, laboratories, offices, confined spaces (e.g., elevators), ventilated or insufficiently ventilated spaces, outdoors, etc.

The products used

Cleaning products are generally aqueous solutions containing surfactants (soaps or other surfactants) to disperse fatty substances in the water. In addition, these aqueous detergents may contain:

• chelating agents (citric acid, for example),

• solubilizing agents to co-solubilize fats (alcohols, glycol ethers, for example),

• acidic or basic agents depending on the type of deposit to be attacked (hydrochloric acid, soda, for example),

• preservatives,

• colorants,

• perfumes…

The modes of action of substances on the body

Substances hazardous to health act in several ways depending on their physical state:

• In the form of gas or vapor, they enter the body through the respiratory tract to the lungs and pass into the bloodstream.

• In the liquid state , they can either act directly on contact with the skin and cause irritation or burns, or penetrate the skin and contaminate the body.

• In their solid state, they can act on the surface of the skin and cause irritation or burns.

Health effects

The health effects caused by substances present in cleaning products are very diverse:

• Skin burns caused by corrosive products such as descaling and drain unblockers that have an immediate effect on the skin and eyes. Consulting the product label and safety data sheet will help you determine whether the product contains corrosive substances. Concentrated sodium hypochlorite solutions (bleach) are corrosive and oxidizing: they can cause very serious injuries if they come into contact with the skin or eyes.

Skin or respiratory irritation caused by ammonia or bleach, for example. Diluted to normal concentrations, sodium hypochlorite solutions are irritating to the eyes.

• Skin or respiratory allergies linked to additives such as perfumes, colorants, preservatives (isothiazolinone).

• Poisoning by inhalation or skin penetration caused for example by volatile or sprayed products. The disorders associated with poisoning will depend on the toxicity of the substances that have entered the body and the exposure dose: they can range from reversible transient symptoms to more severe conditions. Ethanol and isopropanol are well-known central nervous system depressants. In high inhalation exposures, narcotic effects, numbness, headaches may appear; these are generally accompanied by irritation of the eyes and respiratory tract. Inhalation of high concentrations of isopropanol in particular can cause very severe narcotic effects.

The importance of the method of application of hazardous chemicals

The method of application of a product will influence the employee's exposure:

• by spraying (window cleaner, oven cleaner): the sprayed products will become suspended in the air and could thus poison the employee through the skin and by inhalation;

• manually (wipes soaked in product): in the absence of gloves, the product will come into direct contact with the skin and could cause irritation, allergies or even poisoning;

• using a machine (automatic scrubber, pressure washer) or a manual tool (broom, single-brush machine): if the safety instructions for the machine or the cleaning method are not followed, the product may come into contact with the skin or eyes and cause irritation or allergies.

The employee's exposure to the products used will also depend on the place of intervention: in an insufficiently ventilated space, the atmosphere is not renewed much, which will increase the risks of poisoning by inhalation or ingestion (swallowing) when handling products releasing toxic substances; - in a confined space (example: elevator), these risks will be increased, the symptoms being able to appear more quickly.

Preventive measures

Implement appropriate management of the products you use (choice, storage)

Identify the products present in the company and consult the information on the labels.

Replace dangerous products with less dangerous ones.

Provide suitable storage space and comply with product storage conditions.

Limit the quantities of products stored and handled.

Avoid unpacking a product and keep it in its original packaging.

If the product is transferred, identify and label the new container.

Provide a specific and properly ventilated space for preparing products

Handle products safely

Write job descriptions including safety instructions (suitable products, quantities to use, application equipment, application technique, etc.).

Follow the doses prescribed in the supplier's instructions and avoid mixing products.

Favor operating methods that reduce contact with products and the suspension of particles: avoid the use of sprayers.

Choose suitable clothing and provide personal protective equipment appropriate to the task (glasses, gloves, boots, clothing).

Train employees in good practices such as washing their hands before putting on their clothes, removing their gloves while avoiding contact with the product and then washing their hands, etc.

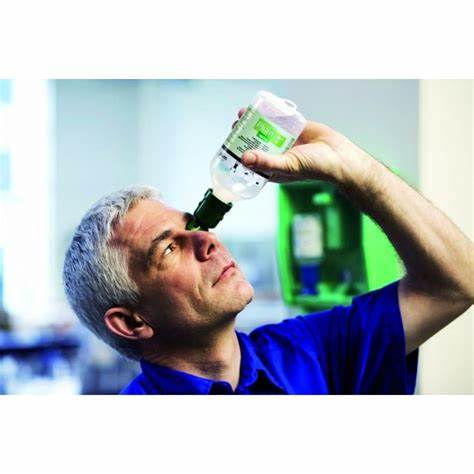

Install first aid supplies (eye wash, etc.) and train employees in their use.

Train and inform employees

Train employees responsible for cleaning (understanding and correct use of information on product labels, safety data sheets and job descriptions).

Educate employees on preventive measures to avoid exposure to products and emergency measures.

Sources:

INRS 2025

Comments