Chemical risks associated with welding processes

- Marc Duvollet

- Aug 24, 2025

- 7 min read

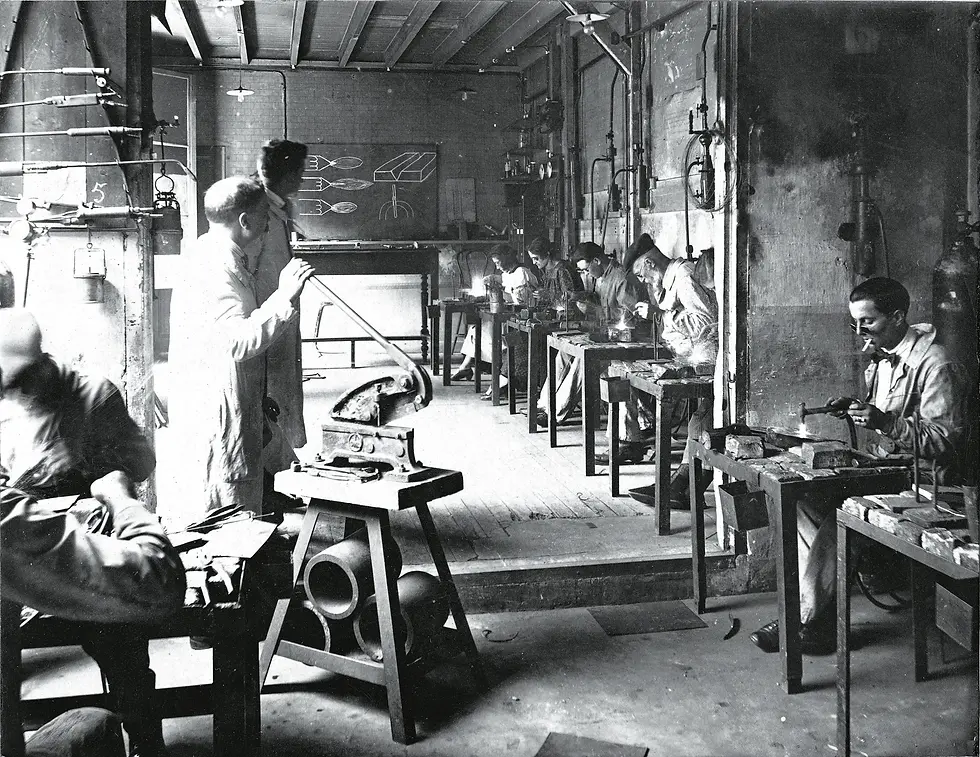

In the lair of workshops where electric arcs crackle, a modern alchemy plays out between man and metal. Welders, these contemporary blacksmiths, shape our world of steel in a silent battle against invisible enemies: the toxic miasmas born of their art. Beneath the protective mask, behind the curtain of sparks, lies a reality darker than the soot of fumes—that of daily exposure to dangerous chemicals.

Overview of the main welding techniques

TIG (Tungsten Inert Gas) welding

A noble process among joining techniques, TIG is distinguished by its infusible tungsten electrode, protected by an inert gas (argon or helium). This demanding method offers surgical precision, particularly appreciated for delicate materials such as stainless steel, aluminum or titanium. Its main advantage lies in the exceptional quality of the beads produced, making it the process of choice for demanding industries (aerospace, nuclear). Although generating little fume, it presents specific risks linked to the emission of ozone and intense UV radiation.

MIG (Metal Inert Gas) welding

A flagship technique in modern workshops, MIG uses a continuously fed consumable electrode wire under inert gas protection. Its speed of execution and adaptability to automation make it a valuable ally for joining common steels and aluminum. However, this productivity is accompanied by a significant generation of metal fumes, requiring reinforced protective measures. It is frequently found in the fields of automotive bodywork and industrial boilermaking.

MAG (Metal Active Gas) welding

A cousin of MIG, MAG differs from it by using an active gas (usually CO₂ or argon/CO₂ mixtures). This characteristic gives it increased penetration, making it particularly suitable for carbon steels. Gas emissions, particularly carbon monoxide, require rigorous ventilation of workstations. Its preferred field covers heavy industrial applications and metal construction.

Arc welding with coated electrodes

A historical and universally widespread method, this process uses consumable electrodes whose coating transforms into a protective gas under the effect of heat. Its main advantage lies in its extreme versatility - it works on practically all metals and in all positions, including outdoors. However, the decomposition of the coating generates fumes particularly laden with toxic elements (chromium, manganese), requiring rigorous respiratory protection. Despite the emergence of more modern techniques, it remains essential for maintenance work and hard-to-access sites.

Chemical risk

The fumes generated by welding operations are a complex and highly toxic mixture, composed of ultrafine particles and dangerous gases, several of which are classified as proven carcinogens by the International Agency for Research on Cancer (group 1). Their composition varies significantly depending on the processes used: welding stainless steels releases hexavalent chromium, a particularly dangerous substance, while other techniques produce fumes of manganese, nickel, lead, or even toxic gases such as ozone and carbon monoxide, not to mention the risk of accidental formation of phosgene, which is particularly insidious.

INRS data reveals an alarming situation: no less than 90% of welding professionals are exposed to concentrations exceeding the Occupational Exposure Limit Values (OEL). Chromium VI, strictly regulated by the decree of July 13, 2006, has its exposure threshold capped at 0.025 mg/m³ according to the binding provisions of the REACH regulation. As for manganese, recently regulated by European Directive 2017/2398, it presents major neurotoxic risks with an OEL set at 0.2 mg/m³.

The particular danger of these fumes lies in their ability to penetrate the body: the extremely fine PM1 particles penetrate deep into the respiratory system, potentially leading to pneumoconiosis or bronchopulmonary cancers. Technical data shows that certain processes such as MIG/MAG or welding with coated electrodes generate emissions three to five times higher than those of TIG welding (according to INRS ED 6116 studies), requiring preventive measures adapted to each work situation.

And when the ultraviolet rays of the arc meet the residues of chlorinated solvents, phosgene is born, the combat gas that caused so much devastation during the Great War.

The Art of Prevention

Faced with these perils, welders must become reverse alchemists, transforming danger into safety.

Controlling emissions at source : The installation of suitable mechanical ventilation systems, in particular articulated arms and extractor hoods compliant with standard NF EN 16985, constitutes the first line of defense against toxic fumes.

Containment of operations : The use of specially designed welding booths, meeting the requirements of Directive 2017/2398/EU, makes it possible to effectively isolate the most emissive processes.

Optimization of techniques : In accordance with article R.4412-58 of the Labor Code, systematic substitution towards less emissive processes (such as the choice of TIG rather than MIG/MAG) is favored when technical constraints allow it.

Process automation : The use of welding robots makes it possible to significantly distance operators from emission sources, thus reducing their exposure.

Personal respiratory protection : According to standard NF EN 12941, one-off interventions require FFP3 masks, while prolonged work requires the wearing of powered respiratory protection devices (PAPR).

Advanced eye protection : Face shields equipped with UV/IR filters, whose protection index is rigorously adapted to the intensity of the process, are essential equipment.

Protective clothing : Flame-retardant overalls certified to EN ISO 11611, supplemented by leather gloves with gauntlets, provide an effective barrier against splashes.

Peripheral protection : Installing anti-UV welding curtains not only protects the operator but also his working environment.

Signage of risk areas : In accordance with the decree of November 4, 1993, clear and visible marking of dangerous areas is mandatory.

Specialized training : DGT circular 2010/04 requires specific training modules on chemical risks as part of SST training.

Exposure time management : Job rotation and limiting continuous exposure time are essential organizational measures.

Preventive maintenance : Article R.4222-10 of the Labor Code requires quarterly inspection of suction systems.

Safe cleaning : Banning dry sweeping in favor of wet methods helps limit the resuspension of metal dust.

Consumables management : Secure storage of electrodes and solvents in dedicated areas is a fundamental requirement.

Environmental monitoring : The decree of October 8, 2018 strictly regulates regular measurements of the concentration of atmospheric pollutants.

Emergency protocols : The presence of first aid equipment specifically adapted to chemical risks is mandatory.

Technical documentation : Job descriptions must be regularly updated and include clearly identifiable hazard pictograms.

Technological innovation : The adoption of integrated suction torches allows smoke emissions to be reduced by up to 70%.

Training and Vigilance

No one can claim to master the art of safe welding without first undergoing a panel of specialized training in occupational health and safety. The mandatory modules, prescribed by Article R. 4412-39, teach welders how to distinguish between benign and deadly fumes, how to adjust their powered air-purifying respirator (PAPR) and interpret the warning signs of poisoning. Welders should also receive ATEX training to identify the factors contributing to a possible explosion (when we know that acetylene is very often used in welding, this makes perfect sense) and fire training, including how to handle fire extinguishers.

Trainers, for their part, must insist on sacred gestures: meticulous hand washing before breaks, the ritual changing of contaminated clothing, and the daily inspection of protective equipment. Because, as Directive 89/391/EEC reminds us, safety is not a gift but a skill that must be acquired and maintained. Of course, the trainers themselves must have received training in fire, chemical, ATEX, and electrical risk prevention, as well as PRAP IBC training to prevent musculoskeletal disorders.

Enhanced Medical Surveillance

Every six months, welders appear before the occupational physician as part of their enhanced medical monitoring (Article R. 4624-23) . The occupational physician interprets the medical results to detect potential illnesses: an excessively high urinary manganese level, reduced lung capacity, etc. These are all encrypted messages that only a trained eye can decode.

Welder's pneumoconiosis : This characteristic pulmonary fibrosis develops after years of inhaling metal particles (particularly during MIG/MAG or arc welding in confined spaces). Its detection is based on radiological monitoring combining chest X-rays and high-resolution CT scans.

Occupational asthma : Welding fumes from galvanized steel or aluminum alloys frequently cause this bronchial hypersensitivity, diagnosed by spirometric tests with specific measurement of FEV1, particularly after exposure.

Lung cancer : Welding stainless steels without adequate ventilation exposes workers to chromium VI, requiring annual CT monitoring for workers with more than 10 years of exposure.

Ethmoid sinus cancer : A dreaded pathology for welders working on stainless steel in a bent position, where fumes stagnate at facial level, detectable by systematic nasal fibroscopy.

Manganism : This Parkinsonian syndrome appears in welders who intensively use manganese-rich electrodes (welding in shipyards, for example), requiring a complete neurological assessment with MRI and urine testing.

Occupational dermatitis : Spark projections on wet skin and repeated contact with nickel-plated electrodes cause these characteristic eczemas, revealed by patch tests.

Keratoconjunctivitis : Frequent in welders who neglect their eye protection during series welding, diagnosed by examination with a flete lamp after the appearance of photophobia.

Occupational deafness : Resulting from the combination of workshop noise and tool vibrations, this progressive impairment is documented by an annual audiogram, especially in industrial boilermaking.

Acute CO poisoning : Particular danger of welding in poorly ventilated tanks, requiring urgent dosage of carboxyhemoglobin in the event of any discomfort in a confined space.

Cognitive disorders : Insidious consequence of prolonged exposure to lead fumes (welding of old parts), assessed by a battery of neuropsychological tests.

Chronic welder's bronchitis : Appears after years of work in underventilated workshops, with EFR showing an irreversible obstructive syndrome.

Heavy metal nephropathies : Renal complications in pipeline welders exposed to cadmium, detected by urine analysis of specific proteins.

Chrome nasal ulcers : Typical lesions of stainless steel welders bending over their workpiece, requiring a rhinoscopy in the event of persistent nasal bleeding.

Cardiovascular pathologies : Aggravated by chronic exposure to ultrafine particles (welding in polluted atmosphere), followed by complete vascular exploration.

Regulatory monitoring : The framework of the decree of 03/01/2016 imposes a complete protocol including blood markers (blood lead, cadmiuria), respiratory function tests and annual neurological examination.

Comments